Foshan Nanhai Dongxu Hydraulic Machinery Co., Ltd., a renowned manufacturer of oil/air coolers, oil coolers, water coolers, hydraulic system assemblies, hydraulic components such as couplings, bell covers, cylinders and accumulators, has shared insight into the critical conditioning requirements of hydraulic fluid in their latest news. The article stated that hydraulic fluid must be maintained at an optimal operating temperature to ensure that the system remains in peak condition.

One of the primary reasons for maintaining hydraulic fluid temperature is to prevent the variance of viscosity that occurs with different temperatures. The viscosity of hydraulic fluid is affected when the temperature drops, so it is crucial to maintain optimum temperature to ensure the integrity of the system. If the viscosity is too low, the hydraulic fluid will not be able to lubricate the system, which leads to excessive wear and tear on the components.

Foshan Nanhai Dongxu Hydraulic Machinery Co., Ltd. stated that they are committed to providing innovative solutions to meet the critical conditioning requirements of hydraulic fluid. They specialize in designing and manufacturing custom heat exchangers and hydraulic system assemblies that maintain the required oil temperature, ensuring that the hydraulic system runs smoothly and efficiently.

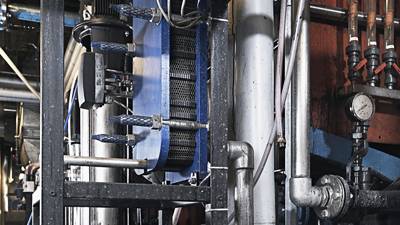

Heat exchangers are essential components of hydraulic systems. They regulate the temperature of the hydraulic fluid by exchanging heat, either by removing heat when the temperature is high or adding heat when the temperature is low. Foshan Nanhai Dongxu Hydraulic Machinery Co., Ltd.'s high-quality heat exchangers are designed to remove excessive heat from the hydraulic fluid, keeping it at the optimal temperature for the various components in the system.

The company's oil/air cooler is a crucial component in regulating hydraulic fluid temperature. This product uses a forced-air cooling system to maintain the hydraulic fluid's temperature at an optimal level. The oil/air cooler regulates the temperature by exchanging heat between the hydraulic fluid and atmospheric air using an air-cooled heat exchanger. This product also features a state-of-the-art filter system that ensures that the hydraulic fluid is free of impurities and contaminants.

Another important product offered by Foshan Nanhai Dongxu Hydraulic Machinery Co., Ltd. is their oil cooler. This product is designed to remove the heat generated by the hydraulic system's operation by exchanging heat between the hydraulic fluid and a coolant. This product features a new cooling concept that allows for efficient heat removal, minimized energy consumption, and improved system performance.

Water coolers are also an essential feature of hydraulic systems. These coolers use water as a cooling medium to regulate the temperature of hydraulic fluid. Foshan Nanhai Dongxu Hydraulic Machinery Co., Ltd. designs and manufactures high-quality water coolers that are effective in regulating hydraulic fluid temperature.

Apart from heat exchangers, Foshan Nanhai Dongxu Hydraulic Machinery Co., Ltd. also designs hydraulic system assemblies, which are pre-assembled hydraulic systems that guarantee efficient operation. These systems are designed to meet the specific needs of clients, ensuring maximum performance reliability.

In conclusion, the critical conditioning requirements of hydraulic fluid, specifically maintaining an optimal operating temperature, is essential to prevent wear and tear, minimize energy consumption, and maximize system performance. Foshan Nanhai Dongxu Hydraulic Machinery Co., Ltd. is committed to providing innovative solutions to meet the critical conditioning requirements of hydraulic fluid, and their range of products, including oil/air coolers, oil coolers, water coolers, hydraulic system assemblies, hydraulic components such as couplings, bell covers, cylinders and accumulators, are designed to achieve this goal. Their state-of-the-art products are of the highest quality and ensure that hydraulic systems run smoothly, efficiently, and at peak performance.